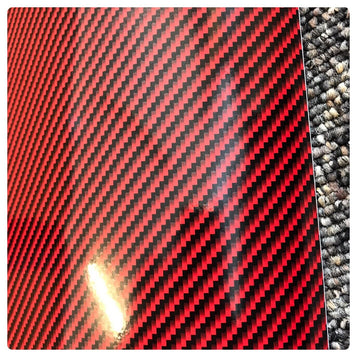

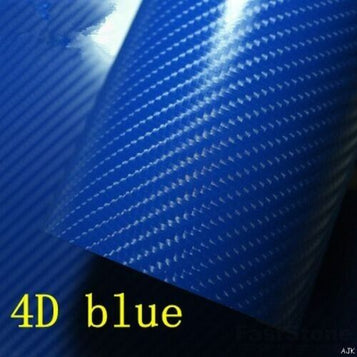

Red 4D Carbon Fiber Car Vinyl Wrap Sheet Film Car-Styling Car-Sticker auto

Automotive Vinyl Wraps Film

Estimated Delivery:

1 to 3 business daysFree Shipping & Returns:

On all orders over $50-

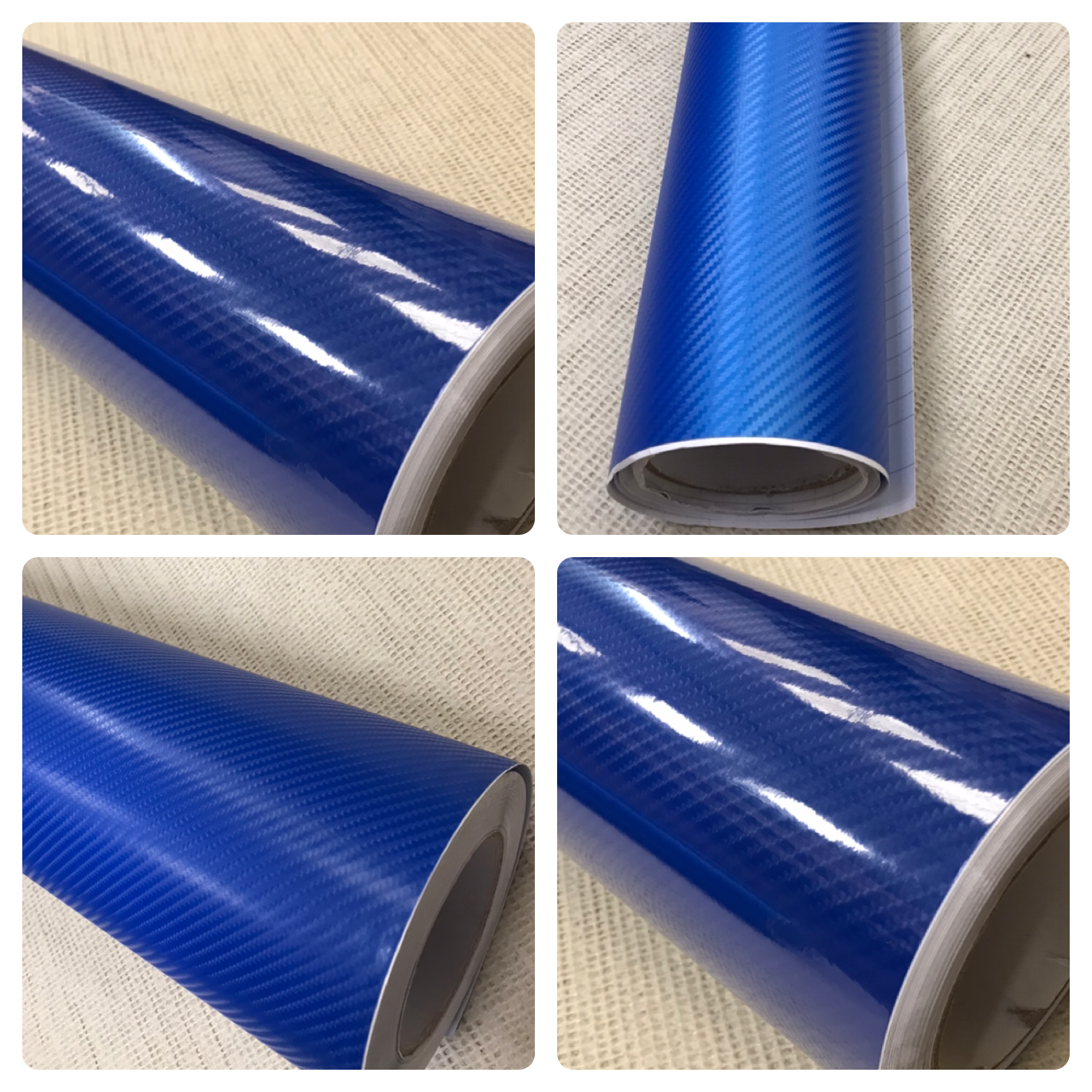

Texture: PVC Thickness: 0.16mm Range of temperature: -20C to 150°C

-

Test of report: European Environmental Standards Release paper: 140gsm air-free bubbles

-

Durability: 3 to 5 years

-

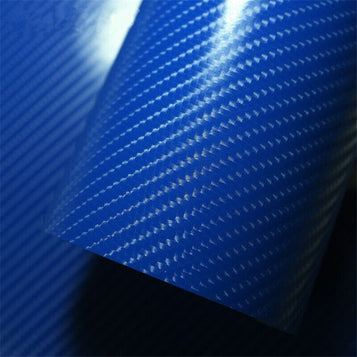

Main Advantage: •1.Polymeric high flexibility PVC film material,stretchable with heat.

-

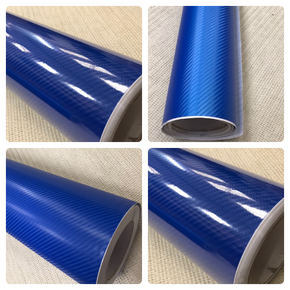

Navy Blue carbon fiber vinyl carbon film with 3D effects!

-

Easy to install,will not fade,chip,crack or peel.

-

Easy to be removed from the car body without any damage.

-

Gluce first-class,no damage the car paint.

-

Prevent your car from ourside damage,such as the water,dirt,grease,weak acides,weak base,oil and so on.

-

Cost-effective and can be cleaned with detergent and water

-

Environmental materials: Non-toxic

-

UV protective finish

-

Width: 1.52m

Instructions

- You will need a heat gun and Squeegeed Cleaning the surface with rubbing alcohol prior to installing the vinyl will help with adhesion and clean any contaminants that may cause imperfections

- the optimum temperature reached during post-heating is 110-120C.

- Make sure the vinyl is down securely in any recesses and channels.

- Check that the vinyl hasn’t lifted in any areas, leaving pockets of air that will cause the film to burn when we apply heat.

- If the film lifts as the temperature increases, it indicates that there is still air beneath the film. This air will expand, causing the film to lift and burn through.

- Working on areas 8-10 inches wide, move your heat gun over the vinyl, until the required temperature is achieved. This may take some time, depending on the quality of your heat gun.

- Repeat this process over all channels and recesses, being sure not to miss any small areas.

- Then apply the same process to any trimmed edges and areas where the film has been overlapped.

- Once post-heating has been completed, and you have inspected the vehicle for any imperfections, the vehicle needs to remain on your premises for the next 12-24 hours. This will allow the adhesive to harden, and the facestock to stabilize.